soul87

-

Gesamte Inhalte

13 -

Benutzer seit

-

Letzter Besuch

Inhaltstyp

Artikel

Galerie

Forum

Kalender

Beiträge erstellt von soul87

-

-

19 minutes ago A2 HL jense wrote:

Thanks a lot!!

This is Including the new ball Joint?

yes, ball joint plus labor

and off course we need to include shipping cost.

-

vor 20 Minuten schrieb A2 HL jense:

any updates on that?

Yes, the price of changing the ball joint is 75 Euro per one control arm.

-

-

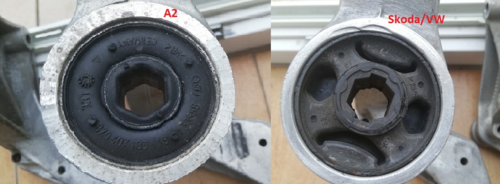

Yes. It turned out that outside diameters are the same. I don't know why some people write that diameters are different.

-

Hello

I wanted to post an update after replacing the control arm rear bushing for 1.2 TDI version (1.2 3L have uniqe control arm bushing which are not available as replacement - only whole console and cost is huge)

In attached images You can find picture of old bushing which is not torn but rubber after 20 years became very hard... second image is new bushing from Polo 9N.

Audi is now more comfortable especially on engine breaking which ECO mode enabled. Low rpm torque vibrations are softer on the body.

Regards

Tomasz

-

Unfortunately no. 1.2 tdi 3L have different softer bushings

-

I want to replace old and hard rear control arm bushing that is located in suspension console/control arm support.

As we know, this bushing is not replaceable in 1.2 control arm support. It only come as whole part and its super expensive.

Option 1 is to buy bushing from 1.4 TDI but it have different design, its all filled with rubber and its probably harder than 1.2 version.

Second option is to buy rubber from polo platform where this bushing is softer so it will suit the soft characteristic of 3L engine version.

But what I found out that bushings from polo/skoda/seat are 63mm , where bushing for a2 are 62mm so the plan is to buy control arm support from VW/Skoda platform with softer design bushing and fit it to an a2.

But yesterday I just realized that ... control arm support from vw platform where I can put softer bushing does not have a place and threads to install sway bar....

-

But i have confirmation that console from polo seat skoda fits a2 1.4 Tdi . One guy on PL forum checked it and it fit. The number part on the cast was the same on his 1.4 Tdi a2 and part from skoda fabia.

Hmmm . Where can be difference here

-

I will come back after confirmation from tencar about price.

At this moment I'm planning to replace rear wishbone bushings .

As we know in 3L they are replaceable with whole suspension console and costs fortune ...

My plan is to get cheap console from polo/fabia/seat car, put new bushing from polo and mount it on mine 1.2 a2.

Wondering if it will fit.

-

Am 2.12.2022 um 12:37 schrieb A2 HL jense:

There are always rumors that there are companies that can exchange this, but I have never seen anything concrete.....

e.g. in the Facebook group

https://www.facebook.com/groups/1726993020922324/

VW Lupo 3L, FSi, Audi A2 3L & SEAT Arosa 3L

Hello

This is my post on facebook

Its not a bullshit

I own a A2 3L and I already replaced ball joint two times in mine aluminium control arm, local workshop in my city http://www.tencar.com.pl/info.htm in Poland did the job

I can post a pictures of control arm in the car with new ball joint

I can post a pictures of control arm in the car with new ball joint

I can replace ball joint in Yours control arms if You will ship them to me and cover shipping costs for both ways and ball joint replacement cost

I need to ask the shop of ball joint replacement when i will provide the control arms alone, because in my case I just left the car for repair.

Regards

Tomasz from Poland

-

2

2

-

-

I'm betting On The 2nd option... IT Just behave like the something in the clutch does not have proper dimensions.

Guide sleeve is fine. I checked IT with endoscope camera.

Below 1.5 v Its always passing SO if the gear selector was defective IT should not be sensitive to clutch voltage ? And ... gear selector is brand new form audi dealer...

Searching is passing fine but when I compare IT to the instruction movies that i found in the forum IT looks like my searching is very fast. It start from 3.5v and finish after droping only a few 0.x volts to values around 3.3 3.2v...

In the instruction movie when someone started calibrstion from 1.67v searching process was alot longer and voltage dropped past 3.0v during searching ..... and slip point establishment at 55 percent.... i Got 80% percent at 1.4v !!!

It looks like my clutch is enganing too early ...

Question is if this Can affect shifting and Downshifting quality.... voltage stability and difference from closed to open clutch is ok - 2volts. So IT this matter that voltage is shifted down? The car behave very harsh .. ITs pissing me off when Im breaking before full stop in Eco Mode the car get a lot of vibrstions on the body when rpms drop to around 1000 before each downshift .. it feel like breaking fights with engine torque during downsifhting On Eco Mode when breaking ....

Albo sometimes On Faster gearchsnges i feel like the gear actuator disengage gear when clutch is not fully released....

Can those two observations be caused by wrong release bearing and shifted voltage On clutch actuator to lower values ? Or only values difference taht need to be 2v is crucial ??

-

Hello, I will write in english because I'm from Poland.

I have a strange problem with my Audi A2 1.2 TDI ANY engine.

In short description, Basic Settings can be made only when hydraulic clutch actuator is set at voltage below 1.5V... when I try to set 1.6-1.9V I got a RTFM 12 error...

Clutch actuator was replaced three times, two times with refubrished and third time with brand new.... And this effect is the same on all three actuators... so I belive that the problem is not with actuator and actuator potentiometer...

In addition I have the feeling that clutch is very sharp, creep point is to hard, so when I left the brake car want to start a liitle bit too hard... gear changes also are harsh... What I noticed that creep point and slip point in group 25 are really high, so at voltage 1.5V I have creep point about 75% and slip point at 85% .... So probably I cant do a Basic settings at 1.9V because then those points will be 99%

I remember One time I was able to do a basic settings at 1.9V only when the engine was hot but after this the car behave very strange, computer was changing the gear at very high revs and after each gearchange the car was doing a jerks....

No errors in engine ECU and Gearbox computer....

Probably everything was started after clutch replacement... I dont know details because clutch was changed by previous owner... I contacted him and he said that harshness started after clutch replacement and the mechanic that replaced it told that the adaptation was done on lower values... becase 1.9 ended with error...

Previous owner told that LUK clutch was installed with new guide sleve.

Im running out of ideas why its happening and why the percetages are shifted up.... From my thinking 85% slip point should be obtained at 1.9V...

[1.2 TDI ANY] Jemand da der seinen Querlenker/Dreieckslenker gewechselt hat?

in Technik

Geschrieben

If someone want You can ship the control arms to me and I can help and take them to tencar for repair and then ship back.

Just pm me

Regards,